Table of Contents

The shipping industry and the environment surrounding its development are on their path towards adaptability and incorporation of the 4th Industrial Revolution’s marvels. Prototyping and testing of newer technologies has been accelerating at an unprecedented rate in the post-Covid era. Truly Smart Ships are about to become the norm and that too, very soon. In this article, we shall look into 5 technological applications that you must seriously consider when undertaking either of the following things: Retrofitting an Operational Vessel to fit upcoming standards; Designing/Commissioning the construction of a new Future-Ready Vessel.

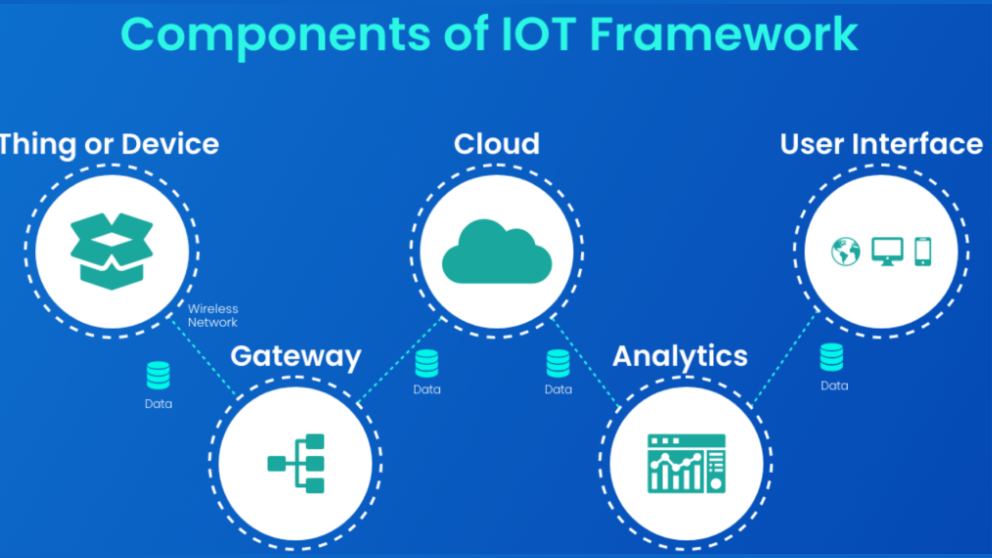

1. IoT integration

With upcoming changes in the viability and increasing ease of implementation of IoT-based frameworks, it has become vital for fleet operators and owners of shipping lines to seriously consider the merits of this new means of real-time cloud-based data acquisition and monitoring in comparison to the conventional more tedious Noon Log reports whose compilation and individual reading, almost always leaves room for a considerably large margin of error/discrepancies. Storage in the cloud has been simplified due to its increased adaptation by various other industries and infrastructural costs, significantly brought down by its increased demand.

Smart Tip: Look into developers/service providers who will tend to your needs by properly analyzing the overall risks and merits of investing in such technologies.

2. Real-Time Data Monitoring

Although efficient, the existing monitoring and sensor data acquisition systems of most vessels suffer from a huge setback; fragmented and non-standardized data whose compilation and accurate monitoring are often delayed and compromised. Tackling such issues requires reliance on the industry standards of Real-Time Monitoring systems; which due to their already existing large use-case in other industries is well refined and standardized for large-scale commercial use. Expect these benefits when you start integrating such systems:

> Enhanced Safety

> Quick Decision Making

> Ease of Compliance and Reporting

3. Non-Invasive Data Acquisition

Old ships need retrofits to upgrade them to Ship 4.0. Unlike conventional ways of data acquisition where in order to acquire point observations, manual work is needed along with sensors which need retrofits. Also, same requires tedious regular checks for validation of reading accuracy, these non-invasive sensors and data acquisition using IIoT will show you the following advancements:

> Equipment integrity preservation

> Condition-based Maintenance

> Continuous evaluation and monitoring

> No downtime for retrofit

Smart tip -> Basic data acquisition just to know the machinery utilization can help identify non essential use.

4. Black Box Modelling

A recommended way for data-driven decision making, this practice is adopted from fin-tech and statistical data analysis. Black Box models in engineering refer to any mathematical model that focuses on an input-output relationship without any attempts at describing the inner functionalities of its constituent sub-systems or parts. It helps with baseline establishment, data quality and operation recognition in maritime. Availability of high frequency data facilitates such analytics.

It is especially helpful in the domain of predictive maintenance, life-cycle assessment cost reductions, and gaining insights on performance optimization techniques for existing vessels. In essence, it harnesses the power of existing machine learning algorithms to establish a reliable input-output correlation database.

Smart tip -> Black box models allow you to obtain valuable insights without ever compromising sensitive operational details.

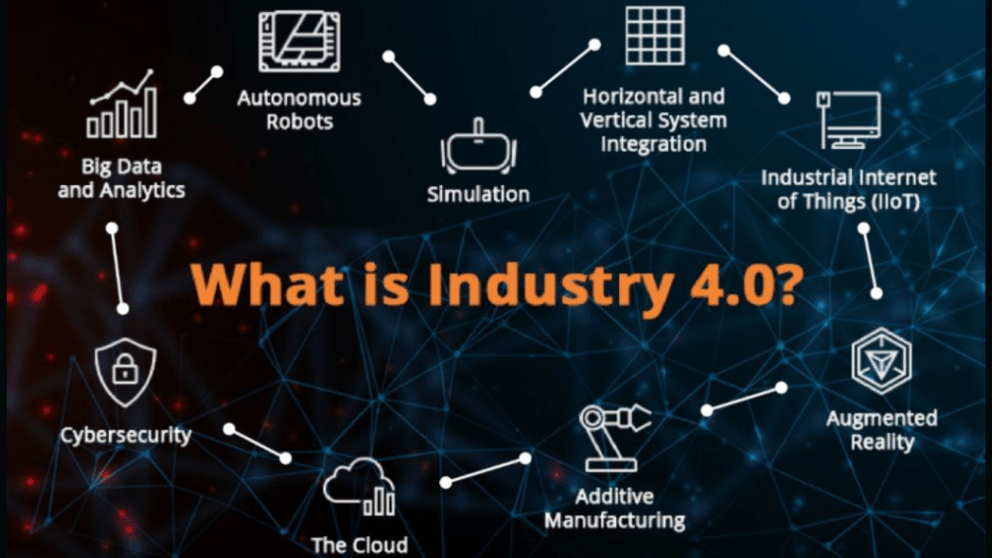

5. Digital Industry 4.0

With the oncoming surge of the 4th Industrial Revolution in the shipping and maritime industry as a whole; an array of changes are about to come; be prepared to see the following things become the norm:

>Supply chain decentralization via Blockchain integration

>Digital Twins becoming a standard

> Data-driven precise decision making

>Autonomous port and logistics facilities

Amid these waves of changes, don’t be swayed away, place your trust in real experience and personnel.

Bonus Tip:

Skilling up your team and collaborating with the right service providers who act as your guides in the changing times is of paramount importance.

Discover more from PerfoMax

Subscribe to get the latest posts sent to your email.