Table of Contents

Flowmeterless Fuel Monitoring for Offshore Vessels: Is it really worth it?

Flowmeters are good; they help you account for every last drop of fuel onboard your vessel. Your crew reports daily counters and totalizers from each flowmeter along with Remaining On Board (ROB) estimates, which help you to understand the state of operating expenses (OPEX). Alternatively, you can go from Bunker Delivery Note (BDN) to BDN; however, you might have a hard time controlling everything in the short term, especially if your vessel uses multiple types of fuels.

Oh yes, the Carbon Intensity Indicator (CII) and Greenhouse Gas Fuel Intensity (GFI) concerns, where you have to account for everything properly. Flowmeters really come in handy and are quite useful in terms of accuracy.

However, in the offshore sector, fuel monitoring systems are motivated purely for addressing inefficiency and, in some cases, unaccounted fuel movement, depending on the region of operation. The numbers could go as high as 40% of bunkered fuel being lost to the aforementioned factors. As far as shore management is concerned, the fuel was used, and to lower this loss, better accounting could be achieved using a fuel monitoring system.

Components of a Typical Fuel Monitoring System Onboard an Offshore Support Vessel (OSV), Considering 5 Engines (2 Propulsion, 3 Gensets)

- 10 Flowmeters (In and Out) for Engines (Coriolis/Mass)

- 1 Flowmeter for Bunker Line (Coriolis/Mass)

- Data Acquisition Infrastructure

- Data Transmission Infrastructure

- Bunker Ticket Printing

- Industrial Computer

- Telemetry System

Complexities Involved in Such a System

- High OPEX of sensors

- Relevant Class approvals required

- More man-days needed for installation

- Flowmeters demand calibration

- Annual Calibration often requires flowmeters to be sent to a laboratory

Even with such a system, there is no guarantee that you would be able to solve the 40% loss.

Now, the market has certain products called flowmeterless Fuel Monitoring Systems. These systems essentially estimate fuel consumption through:

- Fuel Injection System-based consumption;

- Digital Twin-based estimate from engine operational data;

- Typical Bunker-to-Bunker comparison along with day reports.

Such a system can give an accuracy of 95-98%, depending on the amount of data and sophistication of the model.

Such systems generally consist of

- Engine Data Acquisition;

- Automation Management System (AMS) Data Acquisition;

- Day-reports and Bunker report integration to Enterprise Resource Planning (ERP);

- Smart Power Meters;

- Telemetry System;

- Camera reading panels/gauges;

- Tank Gauges.

The fact that most offshore vessels use 4-stroke engines, which have an advanced electronic control system, means this data could be used to work around fuel consumption estimates.

Overall, such systems try to take data from all fuel consumers and estimate consumption based on running duration, load, using pictures with alphanumeric recognition, tank level recognition, etc. This is only an estimate, and it could lose accuracy with a 10% error if the system is not designed properly.

However, these systems are cheaper and easier to operate. Overall Capital Expenditure (CAPEX) is low, and if used properly, the payback period could be less than 6 months with a 15% improvement caused by the installation of the system. Even with respect to retrofitting, these systems could be as simple as to be installed in less than 1 day.

Installing flowmeters in the yard with fabrication could cost up to USD 40,000.

Flowmeters could cost up to USD 120,000.

Auxiliary equipment and approvals would cost USD 40,000.

This brings the overall CAPEX to USD 200,000.

Meanwhile, flowmeterless systems lower the overall price instantly by 50% in terms of CAPEX.

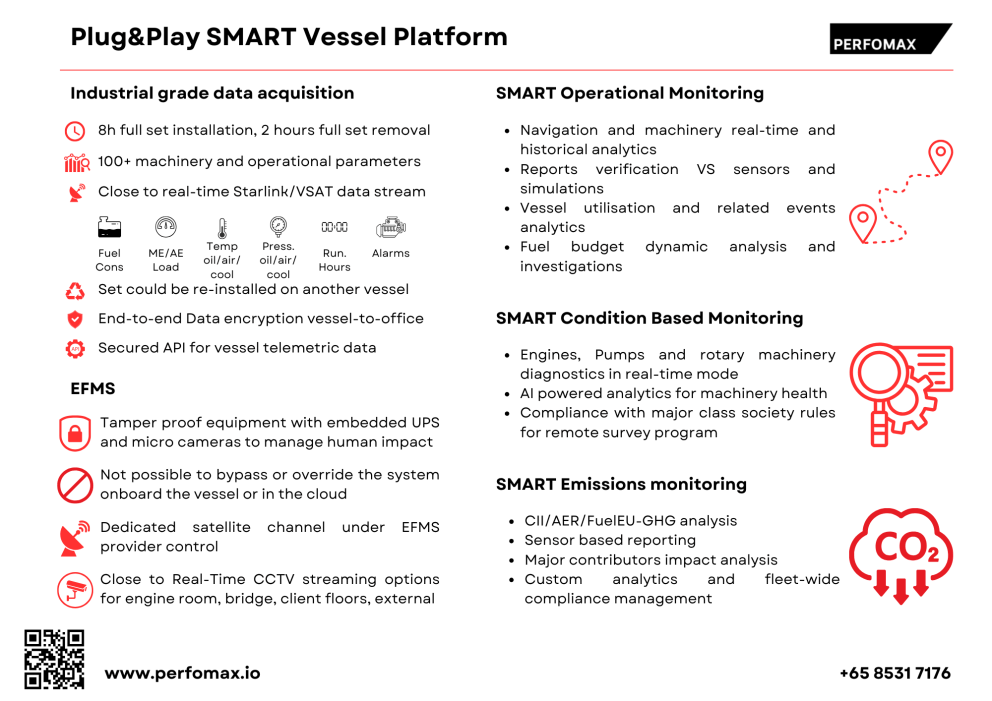

How PERFOMAX solves it?

Our team of experts will be glad to support you on the way to upgrade your fleet, drop us a line on hello@perfomax.io and get a free consultation.

Discover more from PerfoMax

Subscribe to get the latest posts sent to your email.