Table of Contents

Evolution of Digital Twin Design Methodologies

–Shift in Design Methodology

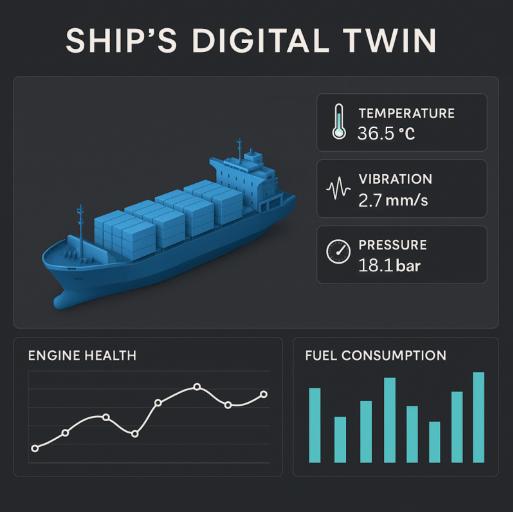

Ship design is evolving from a sequential, point‑based spiral—where each phase depends on completing the prior—toward a concurrent, model‑driven workflow. Design teams are leveraging 3D CAD and high‑fidelity digital twins to map system interdependencies and develop propulsion, tank arrangements, steering gear, and automation subsystems in parallel. Any module change is instantly propagating through performance, stability, efficiency, and cost metrics, virtually eliminating extended rework cycles. This modular, parametric environment is accelerating iteration and is facilitating cross‑disciplinary collaboration, ensuring designs remain reproducible and fully traceable. Early‑stage optimization is becoming routine, enabling smarter, adaptive vessels tailored for sustainability, operational flexibility, and diverse mission profiles, with lifecycle impacts visible in real time and continuously updated within the digital twin framework.

–Driver of Evolution

The market demands faster development cycles with lower initial development cost. This in conjunction with ever increasingly stringent IMO guidelines for increased EEDI indices for new vessels with each passing year, have been the undeniable forces driving rapid evolution in the design methodology and concept design development of newer vessels. Digital twins are becoming a tool that is almost indispensable in order to meet this new demand of the market. It allows for custom structural arrangements, modular bulkhead design while checking for dynamic adjustments to deadweight capacity, steel weight estimations and hydrostatic and CFD optimization workflows. Each subpart is available as a separate reproducible module with each of its characteristics and parameters embedded, for adjustments and direct application of simulation results to design components.

Control Strategy Development

-Model Predictive Control (MPC) & Nonlinear MPC (NMPC)

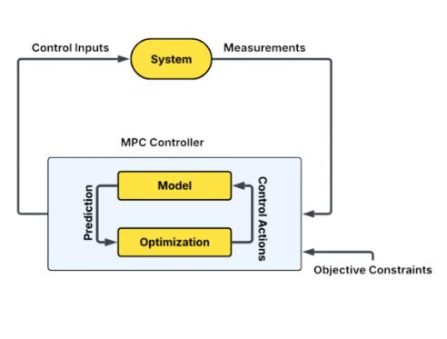

MPC predicts a vessel’s future states over a finite horizon using a linear or simplified dynamic model and solves a constrained optimization at each time step. By minimizing a cost function that balances trajectory tracking, energy use, and actuator limits, it generates optimal control actions—applying only the first before shifting the horizon. In smart‑ship applications, MPC is preferred for coordinated management of multiple subsystems (propulsion, steering, ballast) because it handles multivariable interactions and hard constraints in real time, improving efficiency and safety without excessive computational burden.

NMPC uses the vessel’s full nonlinear dynamics to forecast behavior and solves a nonlinear optimization problem at every control update. This approach captures complex hydrodynamic effects, saturation, and varying operating points with higher fidelity than linear MPC. Although more computationally intensive, NMPC is favored for demanding scenarios—autonomous maneuvering in waves, nonlinear ballast adjustment, or precise hybrid propulsion transitions—because it delivers superior tracking accuracy and robustness, ensuring optimal performance under highly nonlinear, time‑varying maritime conditions.

Application: Energy management, hybrid propulsion dispatch, trajectory/attitude control, dynamic positioning, autonomous navigation.

Effectiveness: Optimizes over prediction horizons, handles constraints, adapts to disturbances—fuel savings of 10–35%, improved speed and heading tracking, balanced SoC in hybrids.

Computational aspect: Heavy; mitigated via explicit MPC, optimization heuristics (e.g. GWO, genetic algorithms), or neural-net accelerators

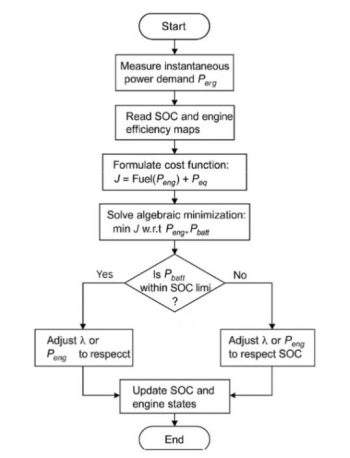

-Equivalent Consumption Minimization Strategy (ECMS)

Equivalent Consumption Minimization Strategy (ECMS) converts electrical energy usage into an “equivalent” fuel cost via a fixed equivalence factor, then dispatches power in real time to minimize total fuel consumption. At each step, ECMS solves a simple optimization—allocating demanded propulsion power between engines and batteries—without long prediction horizons. It’s favored in hybrid‐ship control because it delivers near‑optimal energy management with low computational overhead, easily handles state‑of‑charge constraints, and integrates seamlessly into embedded automation systems for efficient, real‑time propulsion dispatch.

Application: Hybrid propulsion energy dispatch.

Effectiveness: Converts electrical energy use to equivalent fuel cost; good for steady-state, ~20% efficiency improvement with route optimization, though less effective during transient loads without adjustment.

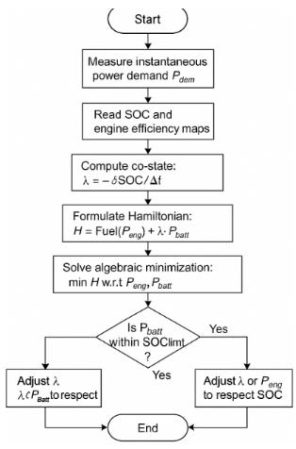

-Pontryagin’s Minimum Principle (PMP)

PMP formulates power‐split as a dynamic optimization using costate variables, yielding necessary conditions for optimal control paths over a given interval. By solving the resulting boundary‐value problem—often via shooting or indirect methods—it determines the time‐optimal allocation of engine and battery power. In marine hybrid systems, PMP is prized for its theoretical optimality and relatively low-dimensional computations, providing high‐fidelity energy management that can outperform heuristic strategies, especially in well‐defined mission profiles with known load trajectories.

Application: Well defined load trajectories

Effectiveness: PMP can efficiently determine optimal real-time control with low computational load, yielding ~5% fuel savings during complex mode-switching

-Learning & Heuristic‑Enhanced Control

This strategy integrates data-driven learning (e.g., reinforcement learning, neural networks) with heuristic methods (fuzzy logic, sliding-mode, genetic algorithms) to adaptively tune controllers in real time. By observing system responses—such as hull motions, propeller loading, and battery state—learning algorithms adjust PID gains, MPC weights, or pitch schedules to optimize performance under changing conditions. In smart ships, it’s used for adaptive heading control in varying seas, online ballast stabilization, and hybrid energy dispatch, delivering robust disturbance rejection and continual performance improvement without manual re-tuning.

Application: Adaptive MPC (via reinforcement, neural networks, evolutionary game theory), fuzzy/autotuning PID, sliding‑mode control for navigation and steering.

Effectiveness: Enhances disturbance rejection, robustness, and adaptiveness in heading/path tracking, thruster control, ballast stabilization

An Illustrative Design Exercise

Here’s an illustrative example that demonstrates the design considerations and estimations/calculations that must be done and considered

- Ship & Prop Inputs

- ∆, V → calm-water resistance (R) (ITTC ’78).

- Shaft power (Ps) and shaft speed (n) (from the motor’s spec).

- Thrust Requirement

![]()

- Advance Coefficient & Target J

![]()

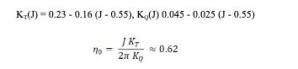

- Open-Water Correlations (ITTC 7.5-02-03)

For a modern 4-blade fixed/CPP propeller (P/D ≈ 0.9, Ae/Ao ≈ 0.55) :

- Diameter Iteration

- Guess Diameter (D)

- Compute J

- Evaluate KT

- Update

![]()

- Repeat until J → JTarget (± 0.002)

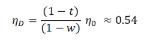

- Torque & Power Check

![]()

Confirm Pcalc ≈ PS

- Cavitation (Q-System)

- Use Q-values for your blade section (from Q-System tables) to find required Cavitation Index (σ).

- Compute

![]()

- Ensure σ ≥ σQ (Q-System minimum, typically 1.2-1.4). Adjust Ae/Ao or reduce loading if not met.

- Propeller Immersion & Sea-Margin (Industry Standard)

- Static hub depth hstatic ≈ 1.4 D (from sister OSV benchmarks); ensure minimum dynamic submergence

![]()

- Per vendor specs, use hstatic ≥ 1.3-1.5 D and add a 5% service margin for squat, hull deflection, and fouling.

What does the future hold?

Recent growth in shipbuilding and maritime markets shouldn’t breed complacency among owners or emerging naval architects; instead, it signals that long‑term survivability hinges on adaptability. Designers must embrace innovative technologies—digital twins, modular systems, green propulsion—and respond swiftly to changing regulations, sustainability demands, and mission profiles. Simultaneously, owners must invest in these advances, integrating flexible designs and performance‑monitoring tools to stay competitive. In this rapidly evolving ecosystem, success will favor those who anticipate shifts, experiment with new methodologies, and collaborate across disciplines.

PERFOMAX team will be glad to provide a free of charge consultation on the SMART vessel implementation and support your innovation journey. To request a consultation please contact us via email hello@ perfomax.io or via whatsapp +(65)8531-7176 and our experts will get back to you same day.

Discover more from PerfoMax

Subscribe to get the latest posts sent to your email.