Table of Contents

Operating on the high-seas and the vast open ocean bring with it a unique set of problem statements which require careful analysis and equally meticuluosly framed solutions. In this article we shall aim to explore a few of the challenges one might encounter:

Challenge 1: Conventional Practices

Conventional invasive flowmeters, data acquisition based solely on noon reports are practices that, although convenient,require regular maintenance and calibration while the periodic noon reports often reflect discrepancies in data acquisition leading to flaws in mathematical modeling of such systems.

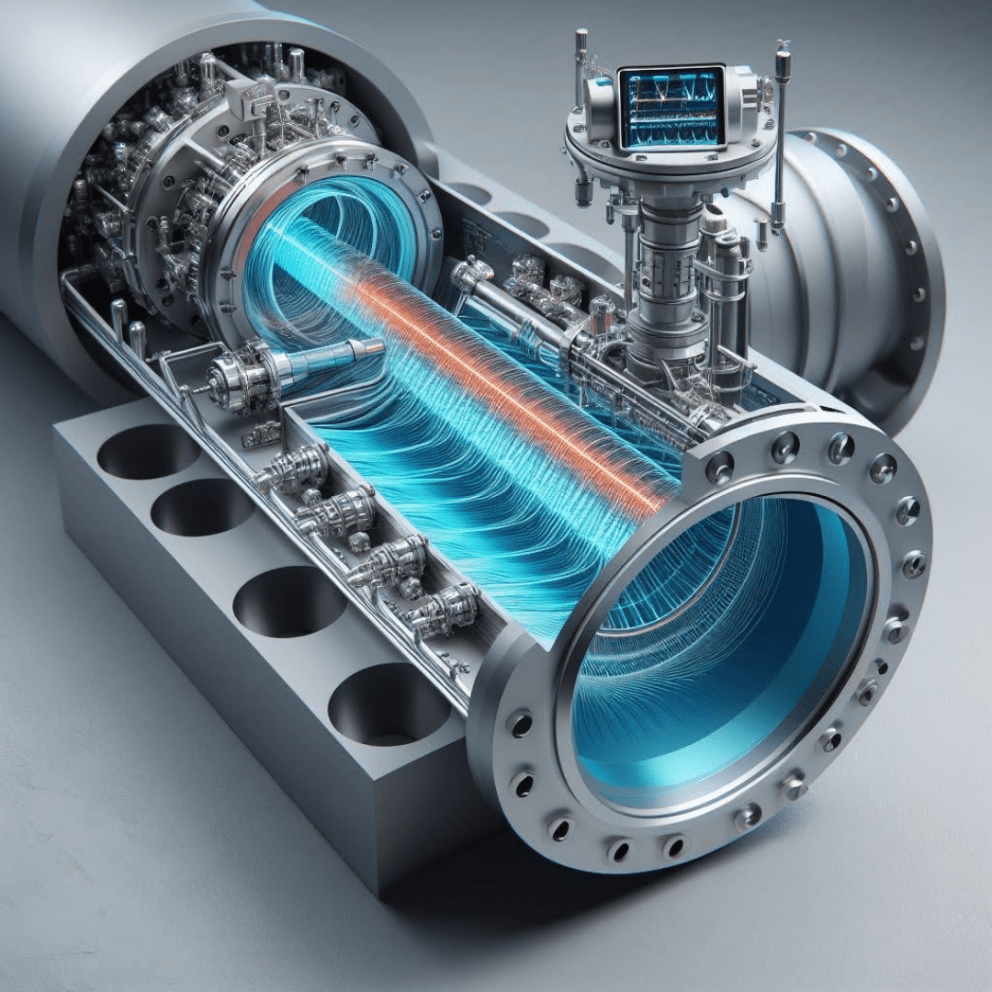

Non-invasive flowmeters play a pivotal role in enhancing the precision of data acquisition from machinery and auxiliary equipment onboard vessels. By seamlessly measuring fluid flow rates without disrupting the flow path, these sensors ensure accurate data collection. Leveraging 5G industrial-grade wireless networks, collected data is transmitted in real-time to monitoring centers. This enables the creation of a performance digital twin of the vessel, replicating its operational state. The digital twin employs advanced analytics to detect anomalies and optimize equipment performance. Through continuous monitoring, potential issues are identified proactively.

Challenge 2: Data Quality

Fuel flow meter data, if solely observed manually, may not reveal trends or anomalies promptly, requiring prolonged scrutiny. Issues like manual inputs for flowmeters, calibration errors, reporting errors et cetera are some of the data quality challenges which occur when a fuel monitoring system does not measure to tackle aforementioned measures. Performance digital twins and real-time data acquisition address these hurdles by leveraging advanced analytics to synthesize and interpret data from disparate IoT sources, including fuel flowmeters. By integrating historical and real-time data, digital twins provide insights into fuel consumption patterns, enabling proactive decision-making and optimization. Bridging the gap between data and holistic insights, digital twins empower operators to optimize fuel consumption effectively, and this reduces costs.

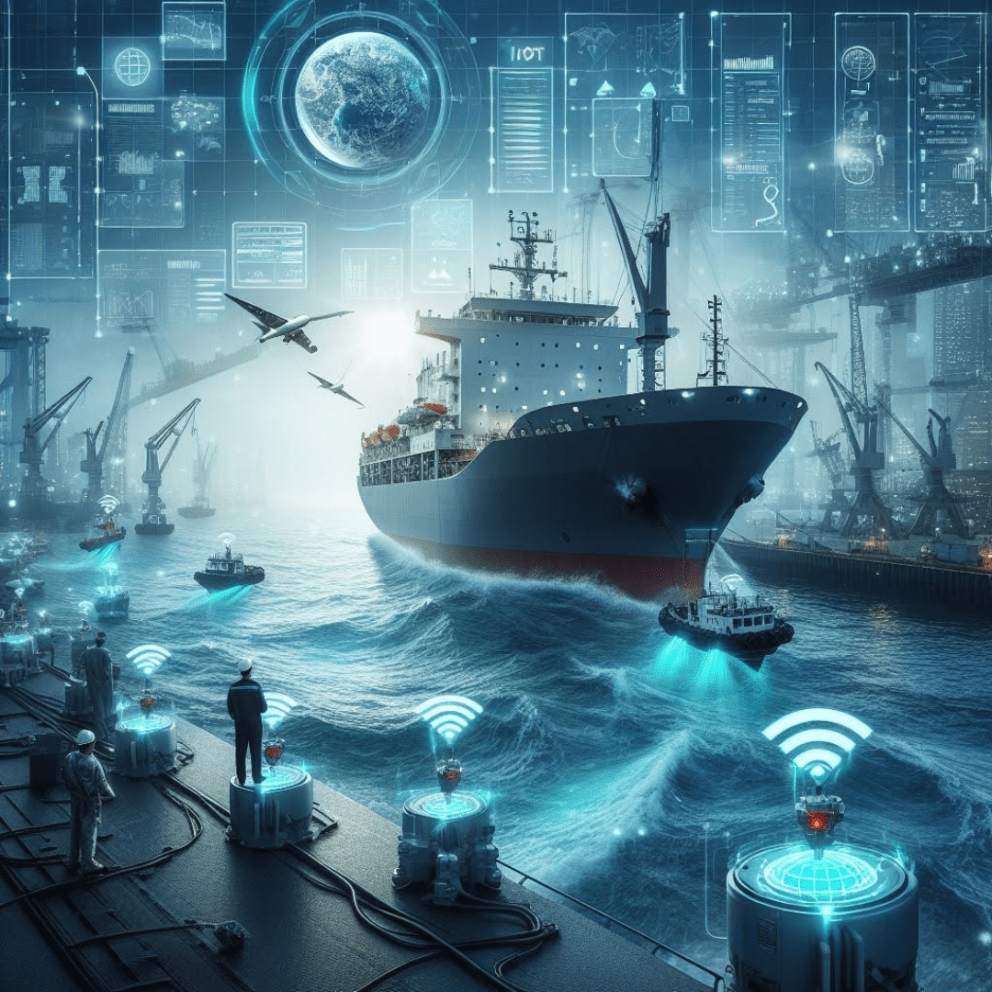

Challenge 3: Readiness

Despite the obvious advantages which adoption of the Ship 4.0 brings to the table, fleet operators and managers are often unwilling to take the risk of investment in such technologies as they may view the ongoing research as volatile and not substantial enough to serve as a replacement for the existing systems, especially because they yield revenue regularly for the firms. However with the newer IMO guidelines growing ever-more stricter,adoption of such technologies will no longer be an option available for exploration but rather a necessary addition.It is therefore the responsibility of both tech operators and fleet managers to collaborate and open constructive dialogue. It is wise to endeavor in technologies which can address the challenges for next 5 years and make your ship ready for 10 years to cope up with new challenges.

Challenge 4: Economics

Conventional invasive flow meters require regular calibration and maintenance, raising CAPEX for retrofits. Non-invasive options like ultrasonic or electromagnetic sensors eliminate this need, reducing initial costs and ongoing maintenance. Integrating digital twins for lifecycle assessment enhances ROI by simulating scenarios and predicting equipment performance. This proactive approach minimizes downtime and maximizes efficiency. By accurately assessing upgrade impacts before implementation, it streamlines operations and improves overall ROI for retrofit projects.

Challenge 5: Lack of advanced analytics

Integration of data from flowmeters is a typical feature of a fuel monitoring system. However, to understand fuel efficiency and identify specific issues need advanced analytics. To effectively utilize this data for analysis, a dedicated system capable of encoding and processing diverse data types is essential. This system must facilitate seamless integration and correlation of disparate data streams to derive actionable insights for optimizing fuel efficiency and enhancing engine performance.

In a nutshell, all of these issues are grave, however, could be solved with concepts of Ship4.0. Read more about what a Ship 4.0 is and how it could benefit you. https://perfomax.io/ships-4-0-the-future-of-smart-shipping/

We at PerfoMax have gathered this experience through research and development, customer experience, pilot projects, and with the expertise we are endeavoring to address these issues with our Vessel Management System via Real-Time Data Monitoring. Contact us to know more about real-time analytics, non-invasive sensors and data acquisition performed within less than 8 hours. .

Discover more from PerfoMax

Subscribe to get the latest posts sent to your email.